surfactant mini flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is a familyenterprise, has 30 years history. It’s established by engineer of Siemens. The production base is locatedin Shanghai Songjiang Hi-Tech Zone. The company has modernized standard factorybuildings and intelligent office buildings, professional gear flow meter andgear pump research department and the most advanced performance test bench inChina.Which imjnmnmnm s a research, development, production, sales, service inone, cross-country, cross-regional integrated enterprise. The company has aGerman high-end gear flow meter and gear pump production technology, has aninternational advanced management model and first-class Production equipment,specializing in the production of mirco flow meter, optional oval gear flowmeter , electromagnetic flow meter, mirco flow meter, piston flow meter, massflow meter, gear flow meter, gear pump and other products. Widely used in waterconservancy, construction, fire protection, Electricity, metallurgy, chemicalindustry, environmental protection, pharmaceuticals, food and other fields.

surfactant mini flow measurement

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Whymany customers gradually from the major international brands MAX, OVAL Obar,KRACHT Clarke and other gradually purchased base deep Oval gear flow meter it?Many customers also have questions: why base depth can be reported Oval gearflow meter so good? This stems from our engineers is a former Siemens seniorengineer, the device is also fully adopted Siemens CNC machining center, thecutting height of 0.001mm, to ensure that our flowmeters minimum flow meter canbe measured to 0.1ml / min, which are at home and abroad are Rare, the currentproducts have been awarded the national measurement certificate, and ISO, SGS,CE, after thousands of customers hundreds of conditions medium test, once againwe are very grateful to the recognition of domestic and foreign customers.Attitude, carrying domestic and foreign customers look forward to working hardto make real benchmarking business.

surfactant mini flow measurement

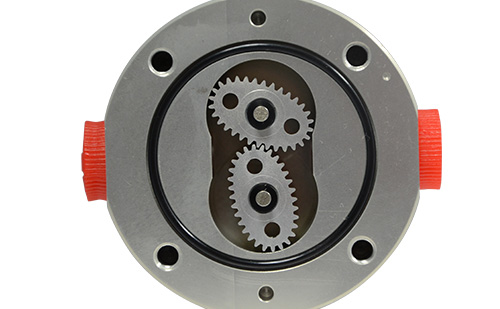

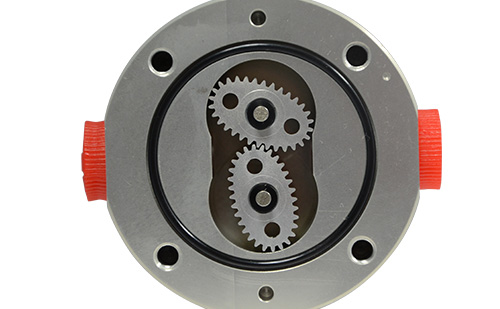

val gear rotor. The gearrotor meshes with the rotating shaft to convey the fluid. The permanent magnetarranged in the rotor is used for the detection of the rotor rotation. Twosensor holes are placed on the upper end to cover the detection sensor. Asealing ring is installed between the housing and the upper and lower end capsto prevent leakage of the measurement fluid. The base depth flowmeter is madeof a material with high wear resistance so that the flowmeter Can guaranteehigh precision measurement within the long service life.

surfactant mini flow measurement

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.